How Zero-Waste Furniture Is Engineered

A technical breakdown of precision manufacturing stages

Digital Material Mapping

Before any physical work begins, every piece of raw material undergoes comprehensive digital analysis. Advanced algorithms map grain patterns, identify optimal cutting paths, and calculate maximum material utilization.

This digital mapping process ensures that every square inch of material is accounted for and planned, eliminating guesswork and waste from the manufacturing process.

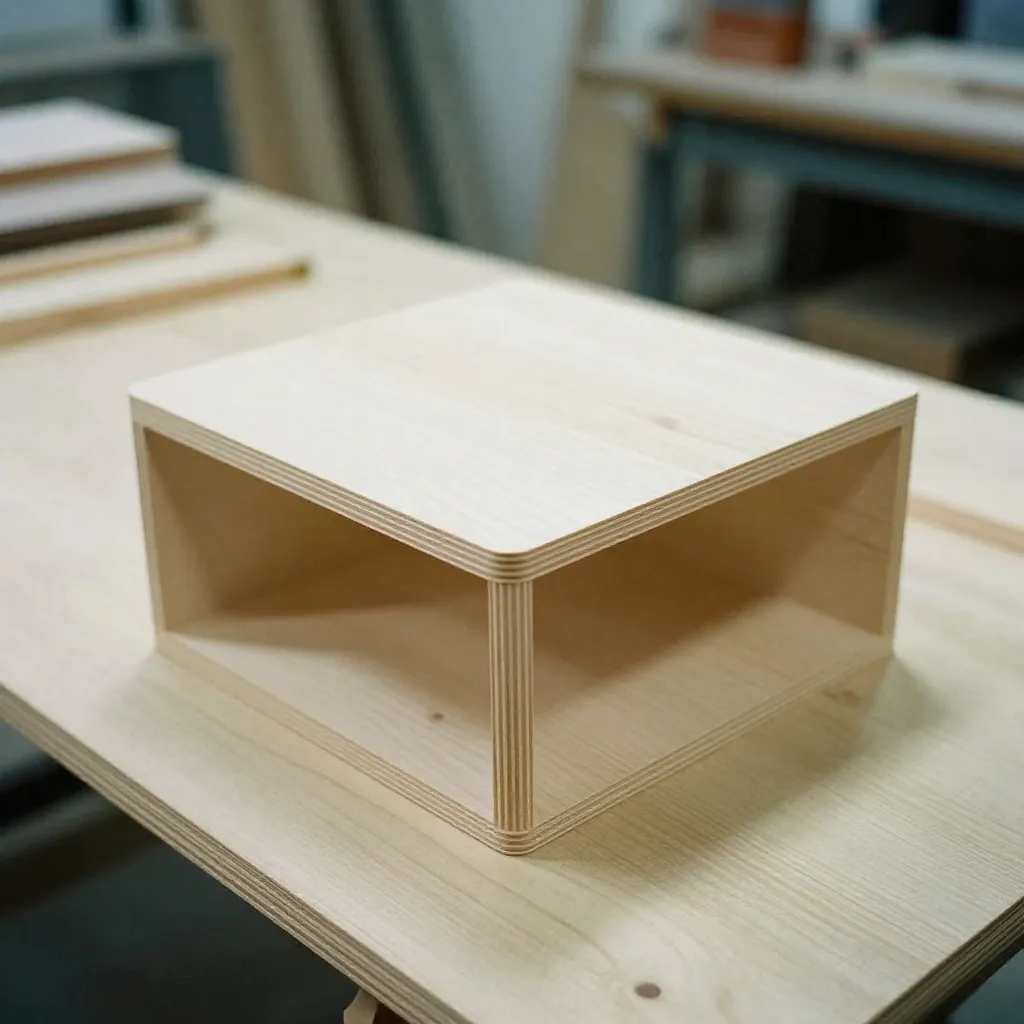

Precision CNC Cutting

Computer Numerical Control (CNC) machines execute cutting plans with millimeter precision. The cutting paths are optimized to minimize material loss while maintaining structural integrity and aesthetic quality.

Real-time monitoring ensures that each cut follows the digital blueprint exactly, with sensors tracking material usage and identifying any deviations immediately.

Smart Joinery Systems

Interlocking Design

Joints are designed to use minimal material while providing maximum strength. Each connection point is calculated to eliminate excess material requirements.

Modular Assembly

Components are designed to fit together seamlessly, allowing for efficient assembly without additional fasteners or support materials.

Reversible Connections

All joints can be disassembled without damage, enabling material recovery and reuse at the end of the product lifecycle.

Reuse of Micro-Offcuts

Even the smallest pieces of material have value in our system. Micro-offcuts are collected, sorted, and repurposed into new products or components.

Wood chips become pressed panels, sawdust becomes composite materials, and even the tiniest scraps find purpose in smaller accessories or decorative elements.

Offcut Utilization

Circular Assembly Design

Design for Disassembly

Every piece is designed with its end-of-life in mind. Components can be easily separated, allowing materials to be recovered and reintroduced into the production cycle.

This approach transforms furniture from a linear product into a circular resource, where materials maintain value across multiple lifecycles.

Material Flow Tracking

Each component is tracked through its entire lifecycle, from raw material to finished product and beyond. This transparency ensures accountability and enables continuous improvement.

Visual Breakdown

Cutting Layouts

Optimized cutting patterns maximize material usage while maintaining design integrity.

Exploded Views

Component separation diagrams show how pieces fit together and can be disassembled.

Material Flow

Visual representation of how materials move through the production system.